Telehandler Buckets & When to use them

In the world of heavy machinery, telehandlers have become an essential machine when it comes to material handling and lifting tasks. Often referred to as a telescopic handler or a rough terrain forklift, the telehandler combines the functionalities of a forklift and a crane. With their versatility and impressive lifting capabilities, telehandlers have revolutionised the way we handle heavy loads in various industries, from the agricultural sector to construction sites. A key component that enhances the functionality of these powerful machines is the telehandler bucket.

If you're wondering what a telehandler bucket is and how it can benefit your operations, you've come to the right place. In this blog, we will delve into the world of telehandler buckets, exploring the crucial factors to consider when choosing one for your machine and discovering the diverse range of applications where these buckets can be utilised. Continue reading to find out more.

Best Uses for your Telehandler Bucket

Telehandler buckets, also known as material buckets, are specially designed attachments that are used to scoop, carry, and transport loose materials. With a wide variety of applications, traditionally undertaken by a wheeled loader or loading shovel, the telehandler has a few main uses:

1. General Material Handling

The telehandler bucket is being used in a range of sectors for extremely diverse jobs. The construction industry have benefitted massively from the introduction of the telehandler bucket as it's allowed them to use the vast width and depth of this attachment to move large amounts of loose material. This is particularly useful for moving piles of aggregates from point to point, clearing sites and even to fill drainage trenches with pea shingle / pea gravel where necessary. Whereas landscaping and agricultural applications vary from scooping animal manure, spreading mulch or topsoil, moving grains and fertiliser and loading hay bales onto trailers. These buckets provide farmers and landscapers with the necessary lifting power and manoeuvrability required to carry out their jobs successfully and quickly.

2. Loading Tarmac Hotboxes

Traditionally, loading tarmac hotboxes required manual labour, often involving a team of workers using shovels and wheelbarrows to fill the hotbox with tarmac or asphalt. This process was time-consuming and labour-intensive, resulting in delays and reduced productivity. But with a telehandler and telehandler bucket, this process has been streamlined to load the hotbox in a fraction of the time. Keeping your loading times to a minimum and avoiding the potential risks of manually loading the material into the vehicle.

3. Road Clearance - Snow Removal & Salt Handling

In regions with harsh winters, the telehandler bucket becomes an invaluable tool for snow removal and salt distribution. Its lifting capacity lets you plough and remove snow from roads, car parks and footpaths and follow it up with salt spreading to help combat ice. Because of the size of the bucket, it's extremely quick and efficient so you can get your jobs done quickly.

4 Features to Look for in a Telehandler Bucket:

Not all telehandler buckets are created equal. There are various features that need to be taken into account to ensure you select the right bucket for your specific needs. From bucket capacity and size to material composition and bucket shape, understanding these considerations is essential for making an informed decision. But we believe there are 4 key features that you should look for to make sure you're getting the best quality bucket for your money:

1. Steel Thickness

You would assume it goes without saying that your bucket should be made of the thickest steel available, but this isn't always the best case scenario. As a general rule, we would say that a thicker steel is better - this particularly applies to the bottom of a bucket as it faces the most force and friction. But if you're mainly handling light materials such as grain and pea shingle then a thinner shell design might be better as it allows the bucket to be made larger without impeding on the weight limit of the telehandler.

2. Hardened or Heat-treated Steel

Another important consideration is whether the bucket contains parts made from hardened steel. Of particular importance is the material of the lip plate as this is another area subjected to extreme force and friction. For example: all Rhinox Telehandler Buckets are fitted with a hardened lip plate which is heat treated to 400HB (Hardness Brinell). This is the first part of the bucket which engages with any material and is often used for scraping the ground. Using a harder material in high touch points ensures that the lifetime of your bucket is maximised.

3. Wear Protection

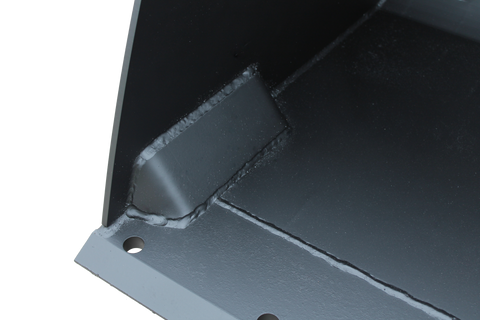

As mentioned, some areas of your bucket will have greater engagement with the ground, therefore being more susceptible to wear. To combat this uneven wear, we would recommend looking for a bucket with additional wear protection. Like Wear Straps and Heal Blocks. These additional pieces of steel protect the bucket as it rubs along the ground, wearing these extra sections before the shell of the bucket itself. In turn massively increasing the wear resistance of your bucket.

The Rhinox telehandler bucket also comes with additional wear gussets located in the front corners to withstand the brunt of the force when digging into a pile of aggregate. Not all manufacturers take the time to fit these extra layers of wear protection, so if maximising your bucket's lifetime is essential to you, make sure to look out for these features on a telehandler bucket.

4. Bolt-on Blade

Although usually made of hardened steel, the lip plate will inevitably be the area of your bucket that wears the fastest. A lot of our customers opt to fit their telehandler buckets with a bolt-on blade to help protect their bucket lip plate from wearing. These bolt-on blades sit below the lip plate to protect the under side of the lip plate from wearing when scraping along the floor or through material. We would particularly recommend fitting one when working with abrasive materials such as pea shingle, salt and recycled materials as the rough edges will wear the steel down quicker.

With their ability to navigate challenging terrains, lift heavy loads, and access complex spaces, telehandlers have truly become a go-to solution for any task that requires reliable and efficient material handling. If you want to know more about Rhinox telehandler buckets or to see one in action, why not take a look at our videos below: