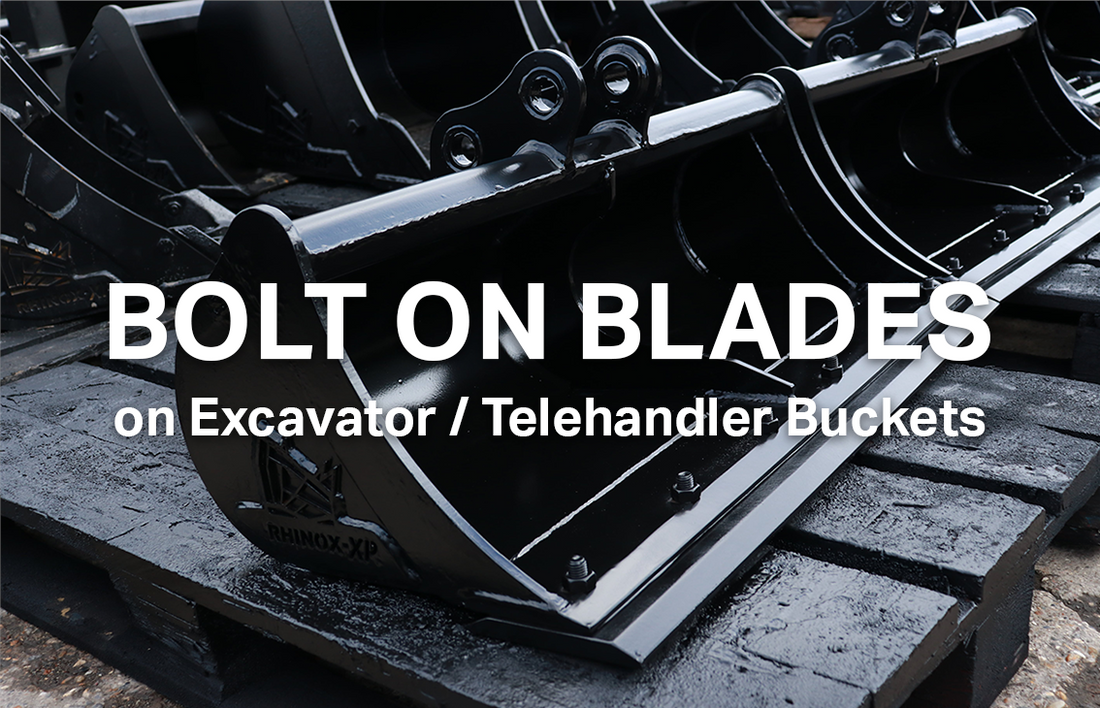

Using a Bolt on Blade on an Excavator / Telehandler Bucket

Why do so many people recommend fitting a bolt-on blade to your digger buckets? In this post we're going to talk about how they can make your buckets last longer and save you money! Keep reading to find out more.

What is a Bolt on Blade?

If you're looking for an answer to the question above then you've probably heard of the term 'Bolt-on Blade' or 'Bold-on Cutting Edge'. A Bolt on Blade is a hardened plate of steel that is bolted, or sometimes welded, to the underneath of your lip plate of your bucket - see images below.

|

|

|

Why should I fit a Bolt-on Blade to my Excavator / Telehandler Bucket?

The simplest answer is, it protects your lip plate from wearing down or becoming damaged beyond repair. A Bolt-on Blade is a piece of hardened steel that is bolted to the front of your Digging Bucket, Grading Bucket or Telehandler Bucket to provide additional durability and resistance. It stops the lip plate wearing back and becoming deformed, misshapen or no longer level.

Digging in harsh environments will wear down the lip plate of your bucket over time, meaning your bucket will be worn to an unsuitable state which will perform inadequately for your jobs. For example, digging in extreme conditions, with a worn down bucket edge will weaken the bucket structure and could cause the bucket shell to crack beyond suitable use. Or, a worn lip plate will become deformed so will no longer be able to create a flat or level finish to the material or surface that you're trying to grade.

Adding a Bolt on Blade, or Bolt on Cutting Edge as they are also known, drastically increases the life of your bucket as you are protecting the edge with additional layer of hardened steel. As well as reinforcing the edge, you are also able to easily replace the worn or damaged cutting edge when required, rather than having to replace your entire bucket or weld in a new lip plate.

As you can imagine, replacing a blade is considerably cheaper and more time effective than replacing your entire bucket or having to re-weld the underneath of your bucket to replace the damaged lip plate. Bolt-on Blades are usually 3x cheaper than the price of a whole new bucket. This means that in the long run you are actually saving a considerable amount of money and time.

Rhinox Bolt on Blades are reversible which means that when you have worn down one side, you are able to remove it, spin it round and reattach it - ready to be used once again. This obviously means you are getting twice the use out of one blade before needing to replace it. See an example of how much money you could be saving below:

3 Ton Grading Bucket

(48 inches)

Bucket Avg. £339

Blade Avg. £95

3 x £95 = £285

You can purchase 3 Reversible Blades for less than the price of 1 bucket.

Remembering that each reversible blade can be used twice!

Bolt on Blades on Digging Buckets

In some applications you may not want to or you may not be allowed to use your Excavator Digging Bucket with teeth, in this case we recommend you always attach a Bolt on Blade in replacement of the teeth for the same reasons we've already discussed.

Replacing your Bolt on Teeth with a Bolt on Blade is ESSENTIAL if you are wanting to put your teeth back on after using your bucket without them. This is because the lip plate will wear down, beyond the drilled holes in the lip plate, which means that you will no longer be able to re-attach your bucket teeth. The blade will protect your lip plate during the applications were a flat edged bucket is necessary and enables you to switch between teeth and a blade when necessary.

So, it's a no brainer - fitting a Bolt on Blade to your Digging Buckets, Grading Buckets or Telehandler Buckets is an essential to making them last longer and saving you time and money on repairing or replacing! If you want to add a Bolt On Blade to your Rhinox Bucket, contact us today via tel: 01430 259259 or email sales@rhinox-group.com, or add a blade to your chosen bucket via the product page on our website.