The Stand-out Rhinox Ripper Tooth Features You Should Know

There are many different excavator Ripper Teeth on the market, which are all made in different ways. The design of each manufacturer's product can impact how they perform and how long your attachment will last, so it's important to research your Ripper Tooth and the key features before you decide to purchase so that you get the most for your money. In this blog, we're going to cover the 4 Stand-out Features of the Rhinox Ripper Tooth that we think you should know before buying. Continue reading to find out more.

4 Stand-out Rhinox Ripper Tooth Features:

Feature 1: Heavy Duty Construction

The first, and one of the most important features of the Rhinox Ripper Tooth, is the heavy duty construction. If you're looking to purchase a Ripper Tooth then you know that they're going to be used in extremely harsh conditions to rip up and remove tough objects stuck in the ground or to break up rough and compact terrain. So this obviously means they need to be strong enough to withstand these environments.

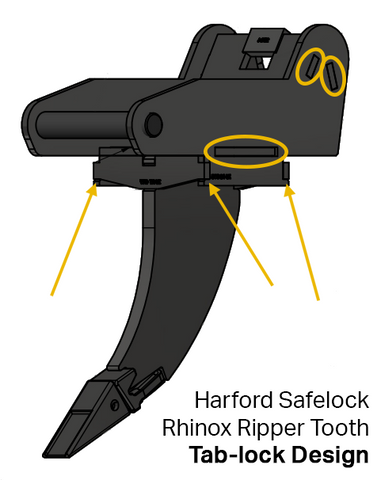

With more than 25 years in the construction industry and through extensive research, we found that manufacturing the hangers or mounting brackets of our Ripper Hooks with a tab-lock design is strongest and the most durable. A tab-lock design means that the attachment is cut out of steel in sections, slotted together like a jigsaw and welded into position to hold the whole structure together. Each section has tabs and holes that match up to create a strong, tight seal.

The main shank of our Ripper Tooth is made of one solid piece of steel which is then tab-locked and welded onto the hangers and the tooth adaptor. This makes the attachment as heavy duty as possible for your hard-wearing jobs. We stand by the strength and built quality of our products so if the welds on your Ripper Hook fail due to poor quality workmanship, we will work with you to get this fixed or replaced as soon as possible. Terms and Conditions apply.

Feature 2: Wear Protection

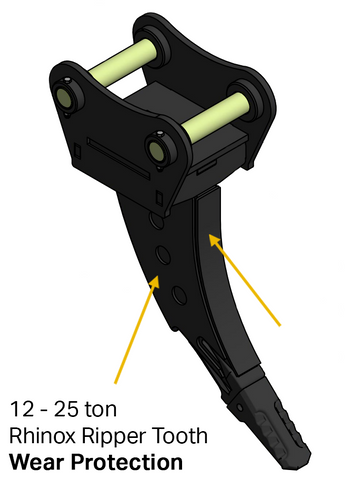

To ensure your Ripper Tooth lasts as long as possible, the tooth and adaptor are hardened to 550 HB (Hardened Brinell). This steel is extremely resistant to harsh, abrasive environments like when breaking through compact rock and trying to remove trees stumps buried in the ground. This level of hardness is essential for areas that experience the most amount of wear, in this case the tooth of the Ripper Hook. The tooth is also manufactured with serrated edges to improve the digging and penetration performance. The serrated edges act similarly to a serrated knife, increasing the efficiency of cutting through material.

On our larger range of Ripper Teeth, 12 to 25 tons, we manufacture the shank with additional layers of steel which are welded to the outside to add an additional layer of protection and help reduce the speed of wear. Ripper Teeth this size are like to be used for extremely heavy duty projects, like in quarries to break up rocks, so we're added this extra protection to make sure your ripper lasts as long as possible.

Feature 3: Replaceable Tooth

Your Rhinox Ripper Tooth is designed to last as long as possible, especially with the heavy duty construction and the hardened cast steel tooth. But alongside these features, the tip of your ripper tooth is also replaceable! It is inevitable that the tooth will wear because of the abrasive material, so to help you prolong the life of your attachment we have made sure that this tip is replaceable. When the serrations start to wear away or it becomes broken during use, you can easily remove the tip of the ripper and replace it with a new one. Why replace your entire attachment when you only need to replace the worn part? You wouldn't get rid of your car once your tyres have worn back.

We can supply you with a brand new Ripper Tooth tip. If you need to purchase a replacement tip for your attachment, you can check out the full range here or don't hesitate to get in contact with us via 01430 259259 and we will place this order for you.

Feature 4: Bolt-in Pins

Another huge benefit of the Rhinox Ripper Tooth is that our 2-pin hangers come with bolt-in pins as standard. Unless you order your ripper with a dedicated hanger set up, like the Martin Hitch or Harford Safelock; then your attachment will come with pins that are secured in place by nuts and bolts. Bolt-in pins are straightforward to fit and replace. Once worn, they are easy to remove, compared to buckets and attachments with weld-in pins which will need the pins grinding out and rewelding. Sometimes the entire hanger bracket will need replacing depending on the wear.

Bolt-in pins in your Ripper Tooth also means you can directly mount your attachment to any machine on the same pin dimensions. If your ripper had weld-in pins, you wouldn't be able to take them out to mount them to your machine, you would only be able to use it with a quick hitch / coupler.

Learn more about the Rhinox Ripper Tooth:

So, there you have it, the 4 Stand-out Features of the Rhinox Ripper Tooth. Use our handy machine selection tool to see if we stock ripper teeth for your excavator. If you need more information or want to speak to one of our Customer Support Team, contact us via tel: 01430 259259 or email sales@rhinox-group.com