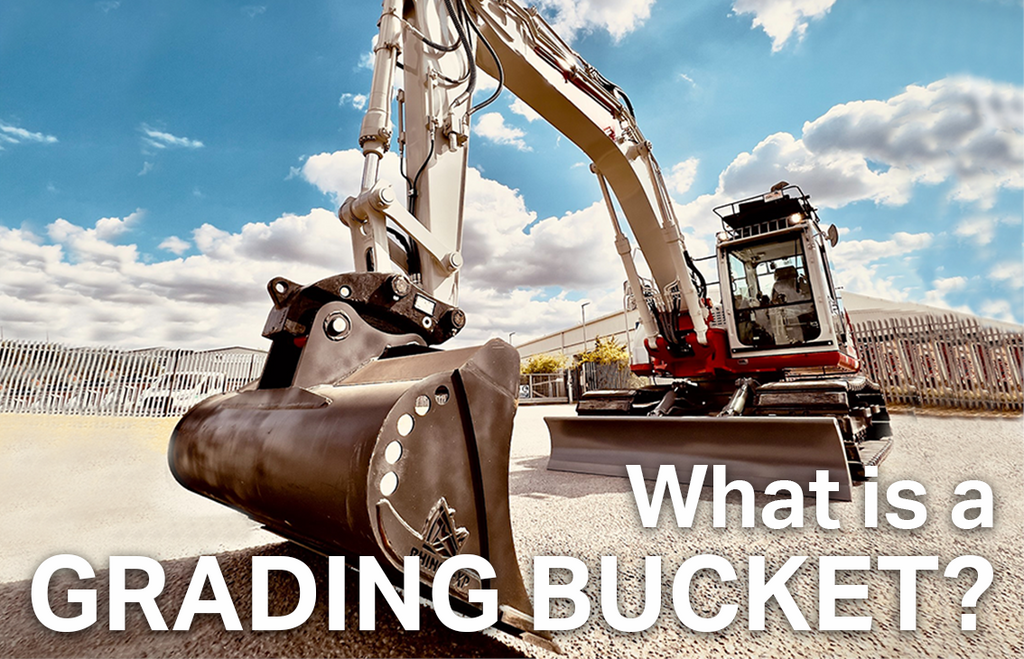

What is a Grading Bucket? And what are they used for?

If you've ever seen a digger / excavator with a selection of buckets, chances are one of those buckets will be a Grading Bucket. They are one of the most common styles of bucket for an excavator and are known by a whole range of different names. Including Dyking Bucket, Finishing Bucket, Ditch Cleaning Bucket and Shuck Bucket. But, what do these buckets look like and what are their best uses? Continue reading to find out more.

A Grading Bucket is a wide, shallow bucket with a straight edge, designed for ground levelling and smoothing out aggregates and soil, as well as bulk moving material. This style of bucket is manufactured with a low profile shell design to allow for increased width without an increase in weight - this would make the bucket too big and overload the excavator.

Grading Buckets can be used on all sizes of excavator / digger and are typically used for laying materials, such as: top soil, crushed aggregate and stones / gravel. One of the most popular uses, is in landscaping where the surface needs to be levelled and profiled before laying turf or weed barrier sheeting before being topped with aggregates. Sometimes the Grading Bucket is also used for bulking or moving large amounts of material onto trucks, trailers or dumpers. It's assumed that because the bucket is wider, it means it can hold more. This is actually false due to the shallow shell design.

"How can I protect my bucket edge from wearing down?"

Digging and Grading jobs can often be very wearing on your buckets. The rough, construction environment will wear down the lip plate of your bucket over time so to combat this problem, excavator bucket manufacturers tend to drill holes in the edge of the bucket (bucket lip plate) so that a Bolt-on Blade / Bolt-on Cutting Edge can be fitted.

A Bolt-on Blade is a piece of hardened steel that can be bolted - or sometimes welded - onto your bucket lip plate to provide additional durability and resistance. Adding a Bolt-on Blade can increase the lifespan of your bucket by 3 - 4x and can be easily removed and replaced with a new one once worn or damaged. This stops you having to replace your entire bucket because of a worn cutting edge. Replacing a blade is 1/3 of the price of replacing your entire bucket so it's a no brainer really!

Learn more about bolt on blades and their use on excavator / telehandler buckets.

Learn more about Grading Buckets & Bolt-on Blades:

CREDITS: Header Image supplied by Willowbrook Plant LTD | Construction and Plant Machinery