What are digger buckets made from?

This is a question that, believe it or not, is more difficult than you think to answer! It depends mainly on the manufacturer of the buckets.

While some digger buckets are made very cheaply, without much thought of lifetime or strength gone in to them. The benefit of this is of course the buckets are also very cheap for the machine operator to buy – these are often referred to as ‘eBay special buckets’, as they are very easily sourced online for very little money. However, as usual, you get what you pay for.

These cheaper buckets are usually made from a very low quality steel, which has not been heat treated or hardened in the places they are supposed to be. This means that the bucket tends to wear very quickly without much working time at all. The end result; you have to buy a new bucket before long.

Another downside, is the fact that the manufacturing quality is not always present. For example, the welding will not be as high quality as can be found on some other buckets, and the lack of quality control means that the likelihood of there being an issue with your buckets fairly high!

What makes Rhinox-Group digger buckets better than the cheaper alternatives?

Of course, no matter what you are shopping for, you always want to know why you should pick one brand over another, and with excavator buckets it’s no different! As a UK digger bucket manufacturer, we strive to make sure all of our buckets are made to the highest standards.

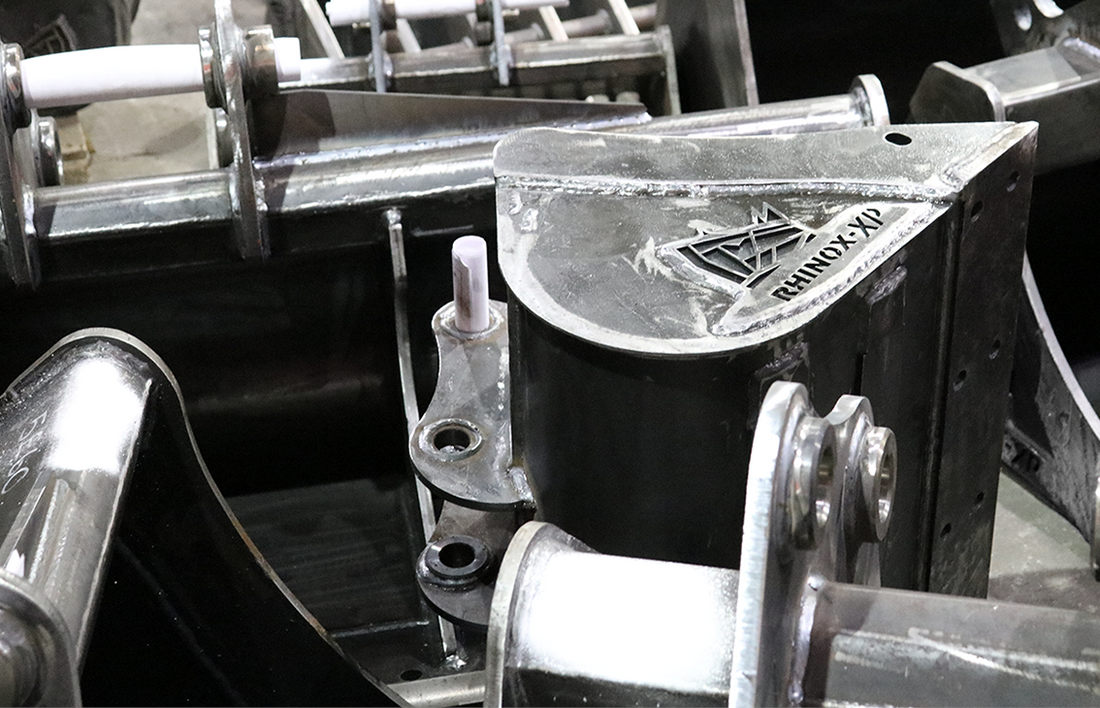

All Rhinox buckets are made out of a very hard wearing steel, and include heat treated components such as the lip plate, wear straps, teeth and side cutters. Different sections are made from different thicknesses and grades of steel as well, such as the front leading edge on all our buckets are made from a much thicker steel to the rest of the bucket. This means that the part that is most prone to wear also has the strongest wear resistance.

None of our buckets leave our site in East Yorkshire without an in-depth quality control procedure taking place. This means that the likelihood of you receiving a bucket of low quality is very unlikely at all!

Here at Rhinox-Group, we are strong believers in a product of high quality, while remaining at a competitive price, rather than a low quality, low cost product that you will be replacing on a more frequent basis.