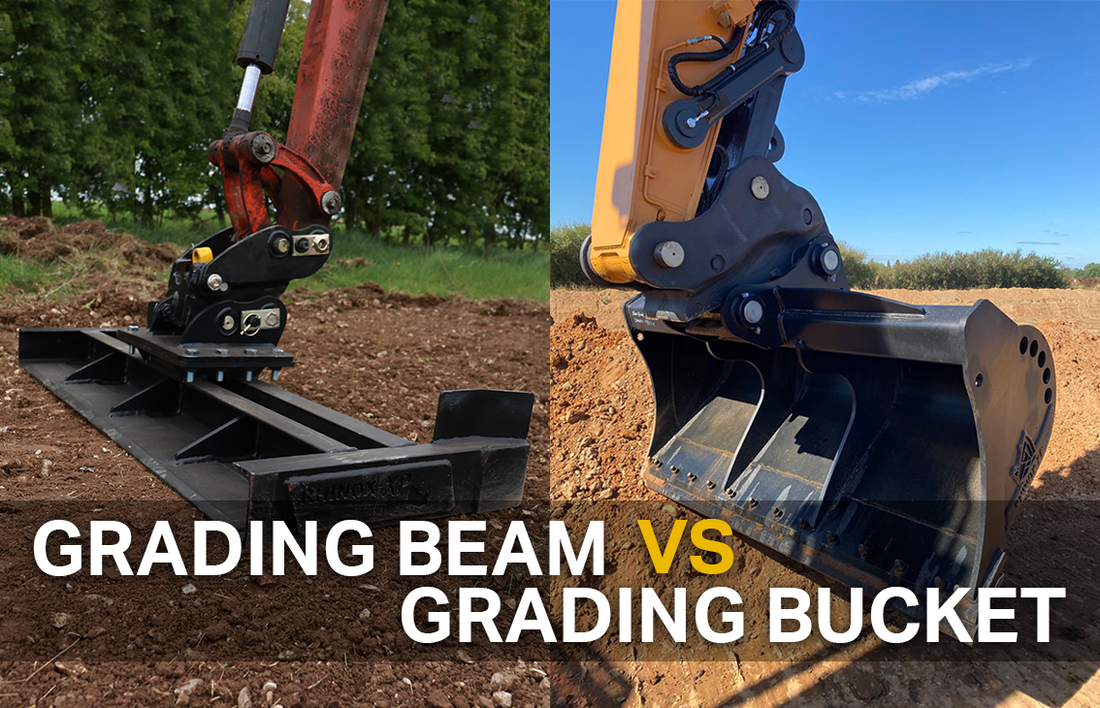

Grading Beam VS Grading Bucket - What suits you best?

Grading Beams are becoming more popular than Grading Buckets in the landscaping and groundworks sectors for levelling and finishing off projects. This up-and-coming excavator attachment is taking the market by storm, but you may be wondering...What is the difference between the Grading Beam and Grading Bucket? And when should you use each attachment for your projects? In this post, we will answer both of these questions to help you decide which attachment suits you best. Keep reading to find out more.

What are the differences between a Grading Beam and Grading Bucket?

Key Differences between the Rhinox Grading Bucket and Grading Beam

Grading BucketAKA: Ditching Bucket, Dyking Bucket |

Grading BeamAKA: Levelling Beam, Grading Bar |

Shallow BucketMade to grade and move material |

Flat Bottomed Beam AttachmentMade to level and profile surfaces |

Additional Wear ProtectionMaximises bucket lifetime |

Heavy Duty ConstructionMaximises beam lifetime |

Optional Bolt-on BladeProvide additional protection to your bucket edge |

Machined Edge BladeAllows for flat grading of materials |

Centre Support FinAdd additional strength to stop bowing |

Guiding FinsAllows for grading close to curbs and objects |

Drainage HolesAllows water to drain out |

Replaceable HeadstockAllows for multiple machine pick-ups |

When should you use a Grading Beam over a Grading Bucket?

The Standard Grading Bucket is a wide, shallow bucket with a straight edge, designed for levelling of aggregates and soil or bulk moving material. The Rhinox Grading Bucket is manufactured with a low profile design to allow for increased width without an increase in weight. It also features a 2-piece side, with a thicker leading edge (front section) to increase durability, which dramatically improves the wear resistance of your bucket. All buckets from the 3-ton range and above can also be fitted with an optional bolt-on blade to increase the wear resistance of the bucket in abrasive work environments.

The Rhinox Grading Beam is a wide, flat bottomed attachment used for levelling and profiling loose aggregates or soil from pre-existing piles. It has been designed and developed to be used instead of the reverse of a Grading Bucket - which some operators tend to do. Using the reverse of a Grading Bucket causes additional wear and therefore reduces the overall lifespan of the bucket. Whereas, the Grading Beam has been specifically designed and developed to carry out the same action without causing damage.

The beam is best used when wanting to grade larger areas of aggregates where using the edge of your grading bucket would take too long. It's a beneficial attachment for landscapers and groundworkers who are trying to achieve a flat, level surface before further site or ground works like laying turd, planting or building. They are most effective with smaller materials like sand, gravel, crushed tarmac, top soil and type 1 aggregate.