Going Green - Carbon Neutral Energy for 2023

Rhinox achieves Carbon Neutrality in 2023 - Our Energy Carbon Footprint has been completely offset!

We are proud to announce that we are still the only excavator bucket and attachment manufacturer in the industry to use carbon neutral energy!

Rhinox Group Ltd has reached another significant milestone in our sustainability journey - certification as carbon neutral for scopes 1 and 2 for the year 2023. This achievement reflects our unwavering commitment to environmental stewardship, showcasing our dedication to reducing our carbon footprint while making a positive impact globally.

- Scope 1 emissions refer to direct emissions that occur from sources that are owned or controlled by Rhinox. For example, emissions from fuel used in company-owned vehicles or emissions created through our manufacturing processes.

- Scope 2 emissions refer to indirect emissions that occur from the consumption of purchased electricity, heat or steam. This includes emissions from the electricity consumed by Rhinox's facilities.

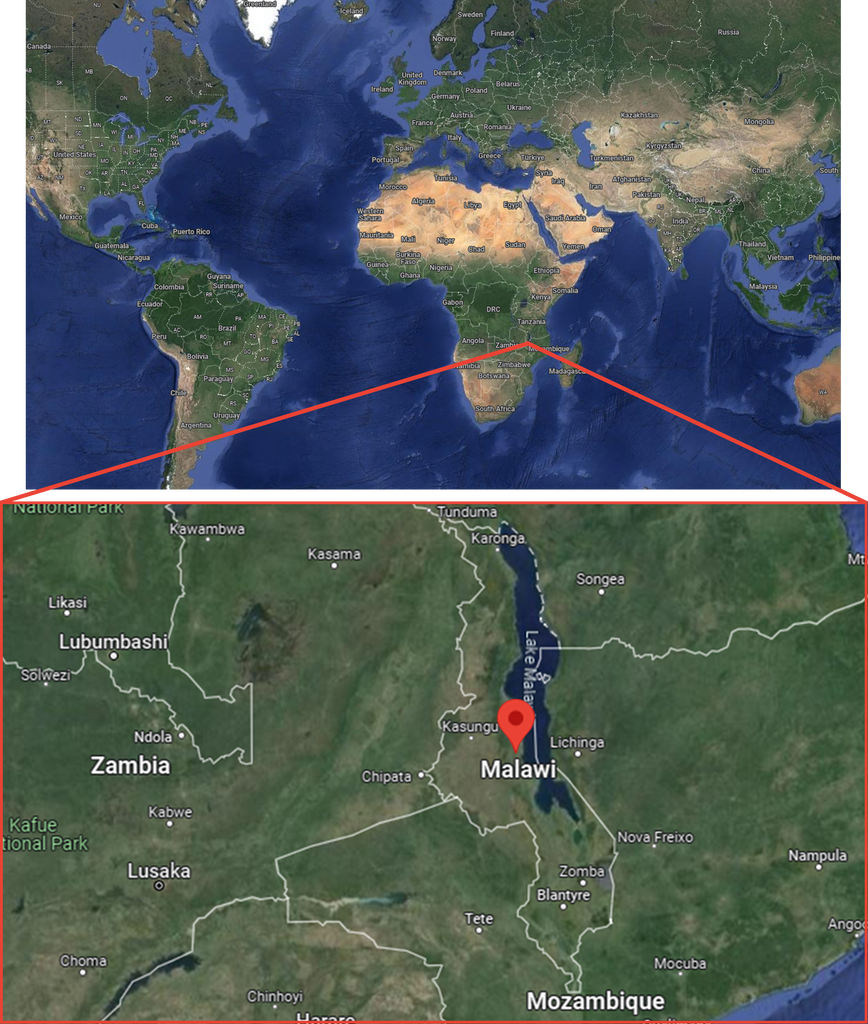

We have achieved this significant milestone by offsetting the carbon emissions associated with the energy used at our East Yorkshire headquarters for the year of 2023, through our investment in the Malawi Cookstove Biomass Conservation project in the South East of Africa. This projects aims to supply improved, energy efficient cooking stoves to homes across Malawi, and promote improved firewood management practises, with an overall goal of reducing the amount of carbon dioxide being pumped into the atmosphere. Reducing the reliance on non-renewable sources, contributes to a more sustainable future.

To calculate and verify our energy carbon footprint for the year of 2023, we partnered with Environmental Strategies Ltd, a leading environmental consultancy and Net Zero Group, a leading carbon offset business. Our decision to continue our partnership with Environmental Strategies Ltd and Net Zero Group underscores our belief in the power of collaboration to drive positive change. By leveraging the expertise and resources of these industry leaders, we ensure the credibility and effectiveness of our carbon neutrality initiatives.

More about: Malawi Cookstove Biomass Conservation Project

The Malawi Cookstove Biomass Conservation project focuses on providing improved energy efficient cookstoves to low-income households in Malawi. Current cooking methods in these areas often rely on 3-stone stoves burning wood or charcoal, leading to deforestation and significant carbon emissions. The project aims to promote improved kitchen and firewood management practices throughout households in the Northern, Central and Southern Districts of Malawi, including the use of less firewood, using a pot lid and soaking legumes before cooking. The improved cookstove technology and practices are intend to replace less efficient methods and avoid source of injuries and accidents.

By distributing improved cookstoves that require less fuel and produce fewer emissions, the project is estimated to save approximately 10,000 tCO2e (tons of carbon dioxide equivalent) per year. This is equal to 25,575,675 miles driven by petrol-powered passenger vehicles or 459,391 propane cylinders used for home barbeques.

Alongside these improvements, the Malawi Cookstove Biomass Conservation project contributes to sustainable forest management by reducing the demand for firewood. It's estimated that over 97% of Malawian households use solid fuel as their primary source of energy so a reduction in demand for these fuels will have a positive impact on the environment. By protecting forests, the project also safeguards essential resources such as clean water, stable soils and vital habitats for wildlife.

|

|

|

Other Sustainable Development Benefits of the Project:

- Good Health and Wellbeing: By mitigating water-borne diseases and diminishing the reliance on fuelwood, the project fosters safer drinking and cooking environments while reducing indoor air pollution.

- Gender Equality: By alleviating the time spent collecting firewood, the new stoves create more time to spent on other tasks. This encourages female participation in becoming sales agents.

- Life on Land: The efficiency improvements of the stoves are helping to mitigate pressure on forests for firewood, thereby decreasing deforestation. This is particularly significant given the alarming 32% reduction in Malawi's forest cover over the last 40 years.

- No Poverty: With less time required to collect fuel for cooking, more time can be spent on other income-generating activities. For some, this allows them to have a job and move further away from poverty.

- Decent Work and Economic Growth: By establishing networks of sales agents, the project contributes to increased employment rates and creates new avenues for income generation within communities.

- Quality Education: The project extends beyond stove distribution; it involves training community members in stove production, thereby enhances local skillsets and ensures Malawi residents don't have to return to old cooking styles.

Our carbon neutrality certification serves as a testament to our commitment to sustainability and sets a precedent for responsible business practices. Looking ahead, we remain steadfast in our commitment to advancing sustainability across our operations and supply chain. By continuing to invest in renewable energy and implement environmentally friendly practices, we aim to further reduce our environmental impact while contributing to a more sustainable future for all. At Rhinox, we believe that renewable energy is a crucial solution to tackling the climate crisis, and we take pride in supporting the development of clean energy projects around the world.

Learn more about how Rhinox is making a difference:

|

|

|